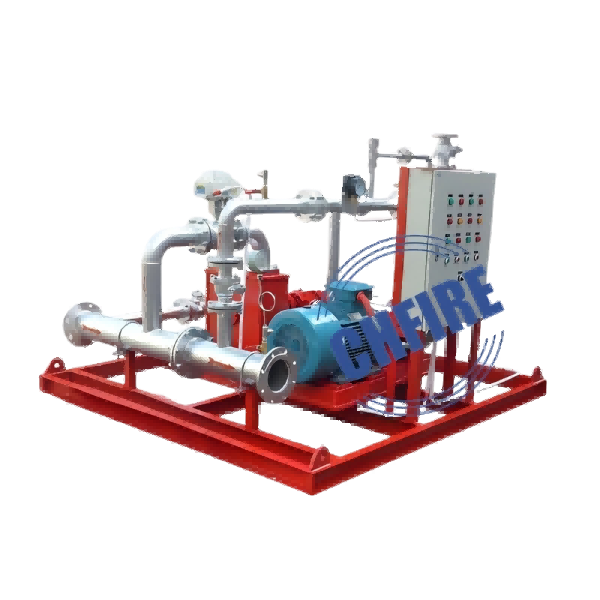

The in-line balanced pressure proportioning system functions by maintaining an equal pressure in the foam concentrate and water inlets to the proportioner. This balancing ability allows the proportioner to be used over a wide range of flows and pressures.

The in-line balanced pressure proportioning system functions by maintaining an equal pressure in the foam concentrate and water inlets to the proportioner. This balancing ability allows the proportioner to be used over a wide range of flows and pressures.

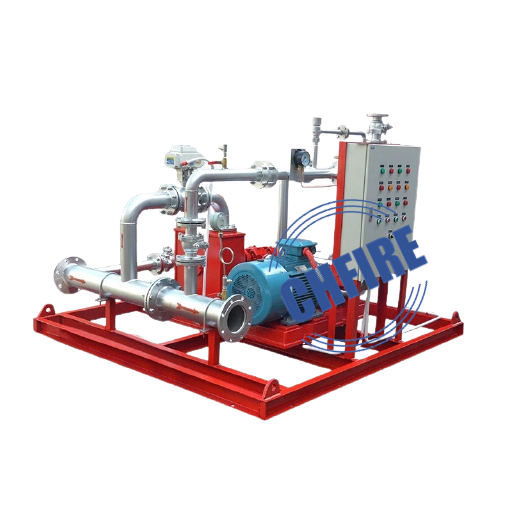

Balance Pressure pump skid-proportioning system accurately controls the flow of foam concentrate in to the water stream.

PHP is an independent proportioning and mixing system that automatically adjusts according to flow and pressure. It is usually installed near the foam tank and connected to the foam tank, fire pressure water source and foam generating equipment through pipes. When a fire occurs, the foam pump starts to suck the foam from the foam tank into the proportioning mixer pipe. After being adjusted by the pressure balance valve and the proportioning mixer, a certain amount of foam is injected into the pressure water flowing through the proportioning mixer and forms a concentrate, which then flows to the foam generating equipment, such as foam guns, foam cannons, etc., and finally produces foam fire extinguishing.

The balanced foam proportioning device is a foam fire extinguishing device used in oil terminals. The foam mixture of this device is mixed by the foam liquid pump pressurizing the foam liquid into the balance valve, and then injected into the proportioning mixer after adjustment by the balance valve. When the water in the main pipeline has different working conditions due to changes in pressure and flow, it is ensured that the device can continuously configure a foam mixture with a more accurate mixing ratio during operation, and supply the foam generating equipment with qualified foam for effective fire extinguishing operations.

Balanced Pressure Foam Proportioning System Foam Skids is widely used in fire fighting system because of its versatility and accuracy. It functions by maintaining an equal pressure in the foam concentrate and water inlets to the proportioner. The balancing ability allows the proportioner to be used over a wide range of flows and pressures. The system will also respond quickly and accurately to changes in the water inlet pressures and flow rates. It is a skid mounted fixed units which are capable of providing foam protection to all types of hazards on land, and it is also excellent for various marine applications. Skid mounting allows the complete proportioning system to be assembled on a common base ready for installation into the customera s water supply.

PHP is an independent proportioning and mixing system that automatically adjusts according to flow and pressure. It is usually installed near the foam tank and connected to the foam tank, fire pressure water source and foam generating equipment through pipes. When a fire occurs, the foam pump starts to suck the foam from the foam tank into the proportioning mixer pipe. After being adjusted by the pressure balance valve and the proportioning mixer, a certain amount of foam is injected into the pressure water flowing through the proportioning mixer and forms a concentrate, which then flows to the foam generating equipment, such as foam guns, foam cannons, etc., and finally produces foam fire extinguishing.

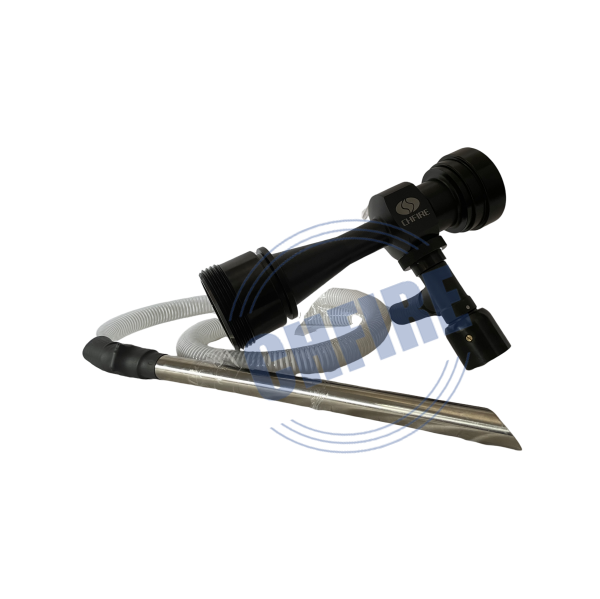

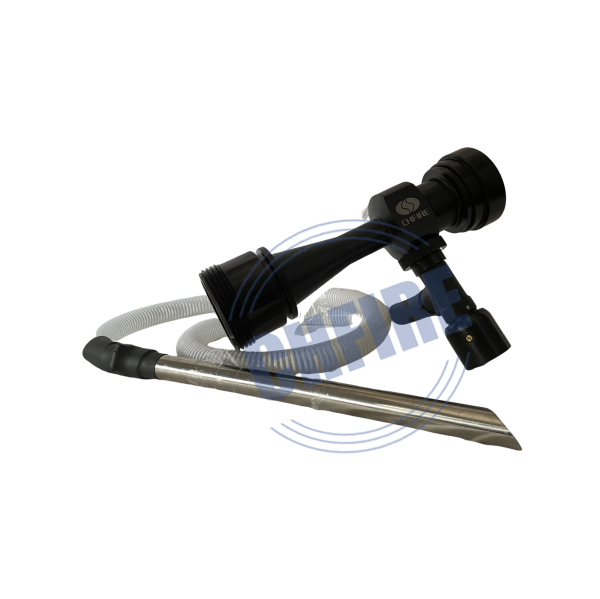

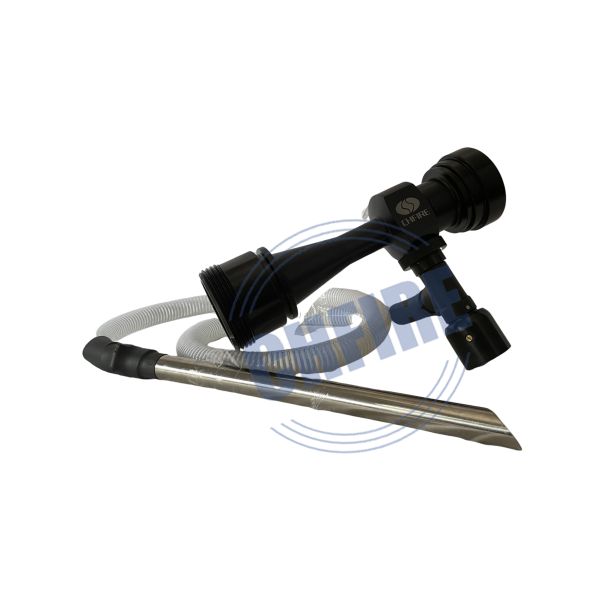

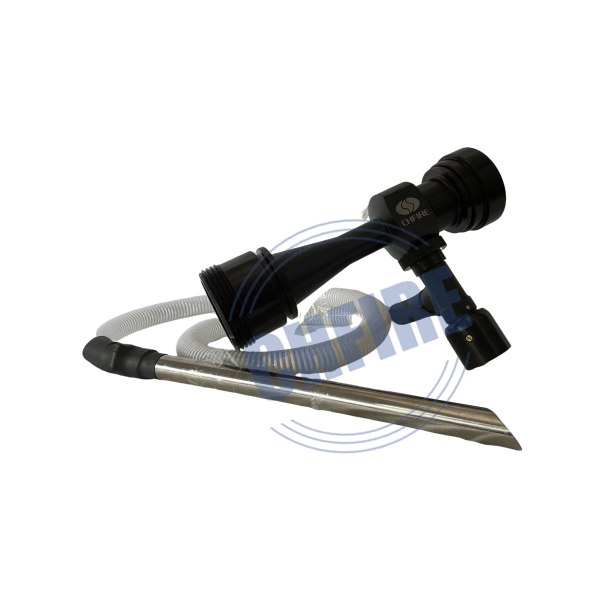

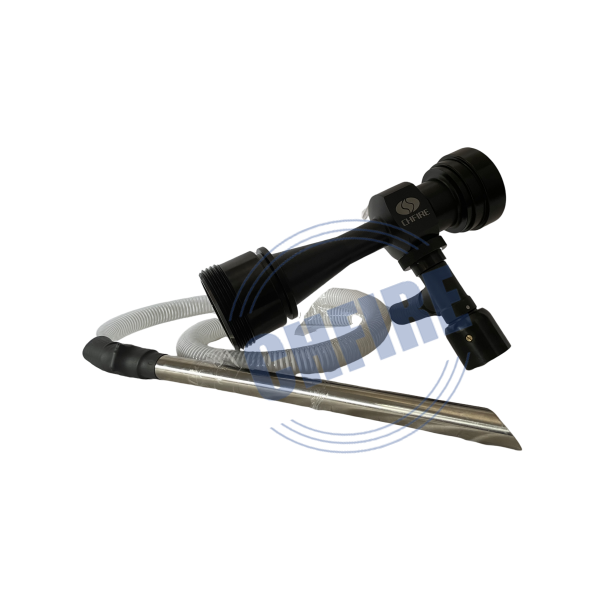

The inline foam inductor is a key component in firefighting systems used to prepare foam mixtures. It precisely mixes foam liquid with water in a preset ratio, and the resulting mixture is delivered to the firefighting equipment via a hose line. It operates at the hose connection between the water pump and the foam generator, and is a crucial component of the firefighting product standardization system.

The inline foam inductor is a key component in firefighting systems used to prepare foam mixtures. It precisely mixes foam liquid with water in a preset ratio, and the resulting mixture is delivered to the firefighting equipment via a hose line. It operates at the hose connection between the water pump and the foam generator, and is a crucial component of the firefighting product standardization system.

The inline foam inductor is a key component in firefighting systems used to prepare foam mixtures. It precisely mixes foam liquid with water in a preset ratio, and the resulting mixture is delivered to the firefighting equipment via a hose line. It operates at the hose connection between the water pump and the foam generator, and is a crucial component of the firefighting product standardization system.

The inline foam inductor is a key component in firefighting systems used to prepare foam mixtures. It precisely mixes foam liquid with water in a preset ratio, and the resulting mixture is delivered to the firefighting equipment via a hose line. It operates at the hose connection between the water pump and the foam generator, and is a crucial component of the firefighting product standardization system.

The inline foam nozzle is a key component in firefighting systems used to prepare foam mixtures. It precisely mixes foam liquid with water in a preset ratio, and the resulting mixture is delivered to the firefighting equipment via a hose line. It operates at the hose connection between the water pump and the foam generator, and is a crucial component of the firefighting product standardization system.

PHP is an independent proportioning and mixing system that automatically adjusts according to flow and pressure. It is usually installed near the foam tank and connected to the foam tank, fire pressure water source and foam generating equipment through pipes. When a fire occurs, the foam pump starts to suck the foam from the foam tank into the proportioning mixer pipe. After being adjusted by the pressure balance valve and the proportioning mixer, a certain amount of foam is injected into the pressure water flowing through the proportioning mixer and forms a concentrate, which then flows to the foam generating equipment, such as foam guns, foam cannons, etc., and finally produces foam fire extinguishing.

Inline Balance Pressure Foam Proportioner (ILBP) is used with positive displacement foam concentrate supply pump. The system controls accurate flow of foam concentrate into the water stream over a wide range of flow rate and pressure.

The foam proportioning device is suitable for oil tank areas and refineries, petrochemical enterprises, hangars, port areas, cargo storage yards, warehouses, gas stations, paint storage areas, etc.

In Line Balanced Pressure Proportioning Systems (ILBP) allow the selection of either foam or water to every discharge device within the foam system.

The balanced foam proportion mixing device is a relatively advanced foam fire extinguishing device, which is particularly suitable for important fire fighting projects such as petrochemical enterprises, large oil depots, oil terminals and offshore drilling platforms.

Place of Origin: Fujian, China Brand Name: CHFIRE Model Number:CH22-15 foam inductor Length: 37 cm Material: Iron/aluminum Color: Red/Yellow Connection: NH, Storz, Instant, Gost, Machino (1.5", 2",2.5") Inlet: 2.5" British aluminum joints male Outlet: 2.5" female Branch pipe: 1 inch Mixing Ratio: 3%-6%

Place of Origin:Fujian, China Brand Name: CHFIRE Model Number: CH22-17 foam generator Type: PCL/PC Working pressure: 0.3~0.6 MPa Nominal pressure: 0.5Mpa Rated flow: 4/8/16/24 L/S Outlet: 4"

Place of Origin: Fujian, China Brand Name: CHFIRE Model Number: CH-22-10 foam bladder tank, PHYM Rate of Flow: 32 L/S, 48 L/S, 80 L/S Inlet and Outlet: DN100 - DN250 Mixing Ratio: 3% -6% Foam Tank Material: Carbon Steel Tank Capacity: 500L and more

Place of Origin: Fujian, China Brand Name: CHFIRE Model Number: CH-22-10 foam bladder tank, PHYM Rate of Flow: 32 L/S, 48 L/S, 80 L/S Inlet and Outlet: DN100 - DN250 Mixing Ratio: 3% -6% Foam Tank Material: Carbon Steel Tank Capacity: 500L and more